Chapter

1

Powering the

LED

The best place to start is to just make one single LED light up. In

this chapter we will look at the three components necessary to do this:

the LED, the resistor, and the battery.

Please do

not connect the LED directly up to a 9v battery, there might be a

slight flash, but then the LED won't work ever again.

LEDs can handle only a limited amount of current. An LED can last for

longer than you will live, when you use it at it's rated current, or it

can be blown up in an instant if the current is not controlled.

LEDs that are in flashlights are usually specially designed to run at

the same voltage as the battery. It can be difficult to find these LEDs

sold separately, so replacing the LED in a flashlight can be

problematic.

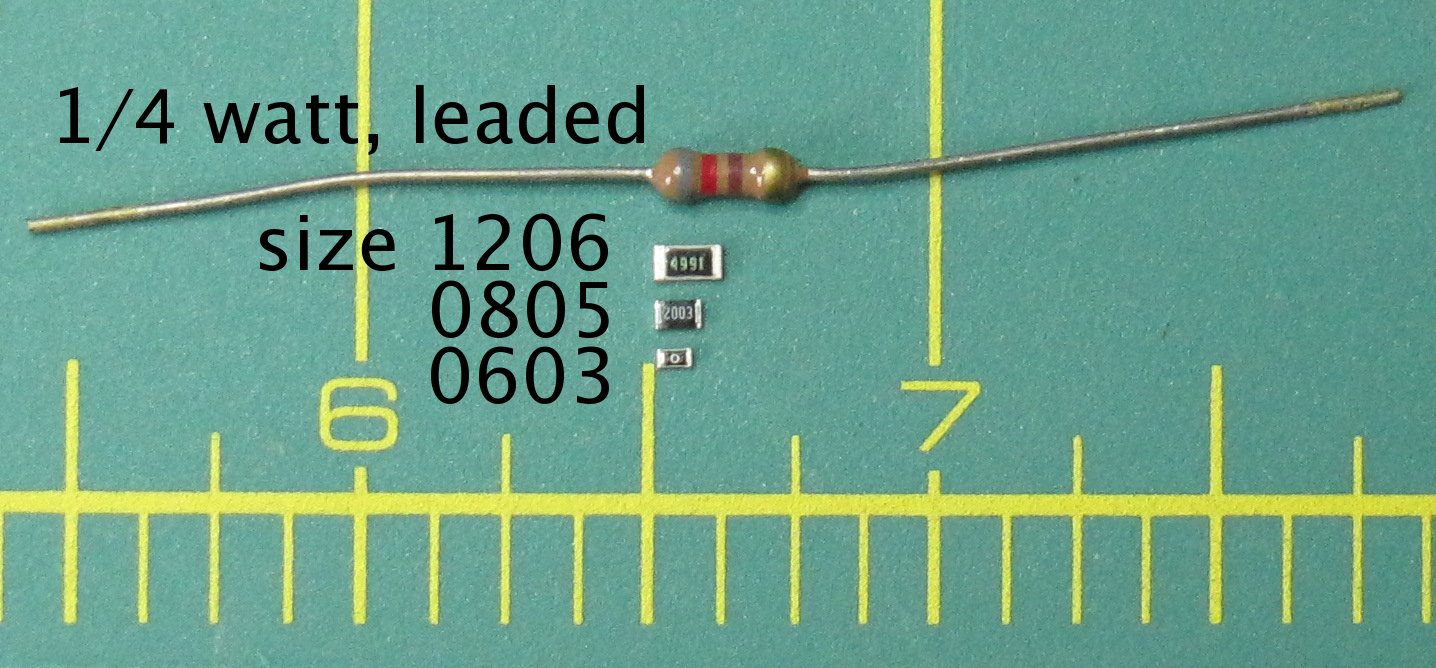

The most common way to limit

the current

in an LED is by using a resistor. Resistors come in various shapes and

sizes, but nearly all of them have a wire or a pad on each side. The

more modern resistors are tiny flat pieces of ceramic that solder

directly onto a printed circuit board.

Some

resistors are larger size so that they can convert more power into heat

without over-heating. When the resistor has more surface area exposed

to the air, more power can be converted into heat without the

temperature of the resistor becoming too high. Resistors have a power

rating in watts. This rating is usually for when the resistor is used

at normal room temperature.

The resistor needs to

be a

different value depending on the voltage and the amount of current that

the LED was designed for. You may choose the perfect value of the

resistor by using a math formula that will be explained later. The

smaller the value of the resistor, the brighter the LED will be. If the

resistor value is too small, the maximum rated current for the LED will

be exceeded and it will burn out. If the resistor value is too large,

the LED will be really dim.

Nearly all

LEDs will light up with the following resistor values:

3v 300

ohms, 5v 500 ohms, 9v 900 ohms, 12v 1200 ohms, 24v 2400 ohms.

There is a pattern here. Just add two zeros to the voltage, choose that

value of resistor, and you can safely test out nearly any LED to see if

it is working. This is a safe current for all but the really tiny, or

super low current LEDs. The LED will not be very bright, but you will

be able to easily see it light up. LEDs only light up when the polarity

is correct. This means that you might need to reverse the connections

to the + and – side of the LED if it does not light up the

first

time.

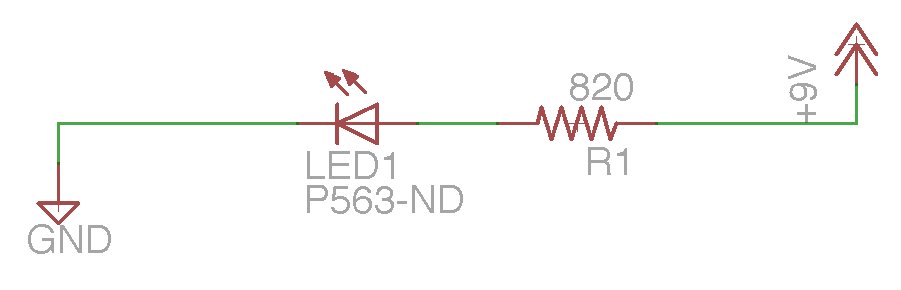

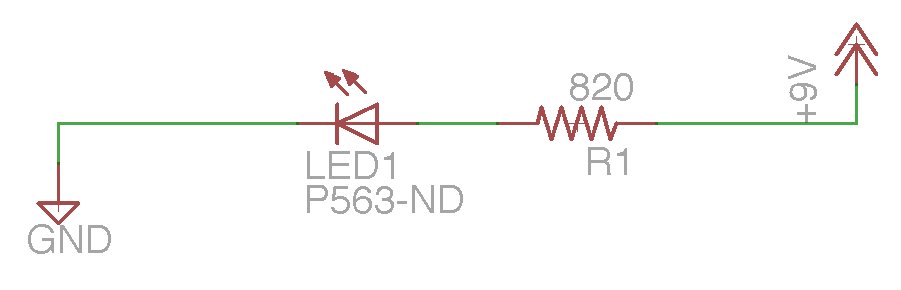

This is a schematic of the circuit

that we will be building:

So lets hook one up and see it light up. If you are familiar with

soldering and hooking up LEDs, you may want to just skip to the next

chapter.

We will start with the tools that you will

need:

The Weller is nice, but if you are just starting out, a 15 watt

soldering iron from Radio Shack, or Ebay will do just fine.

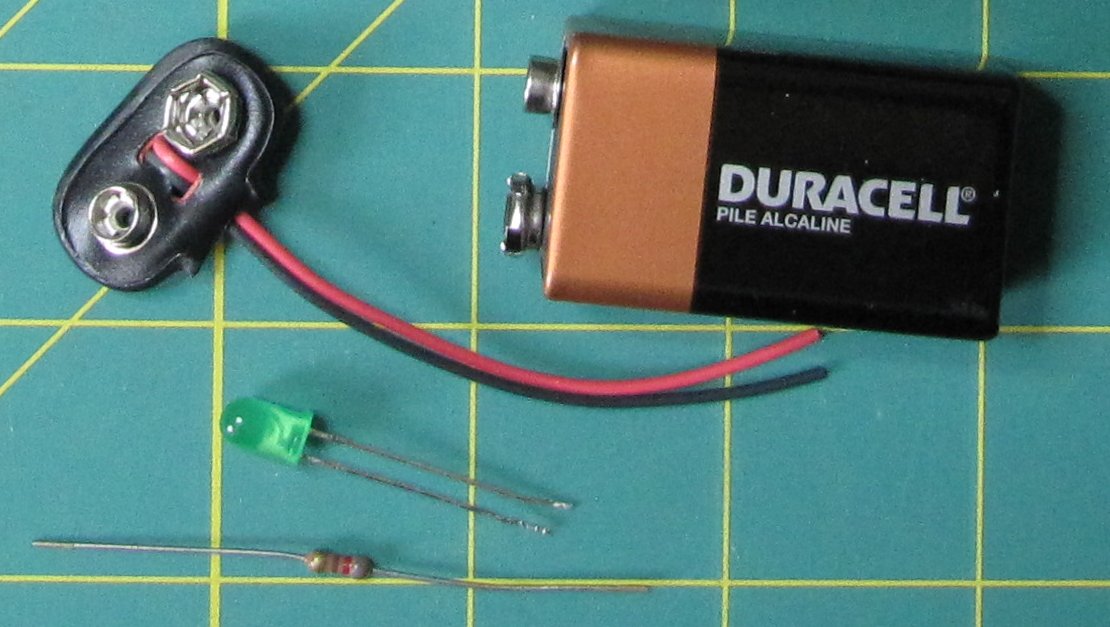

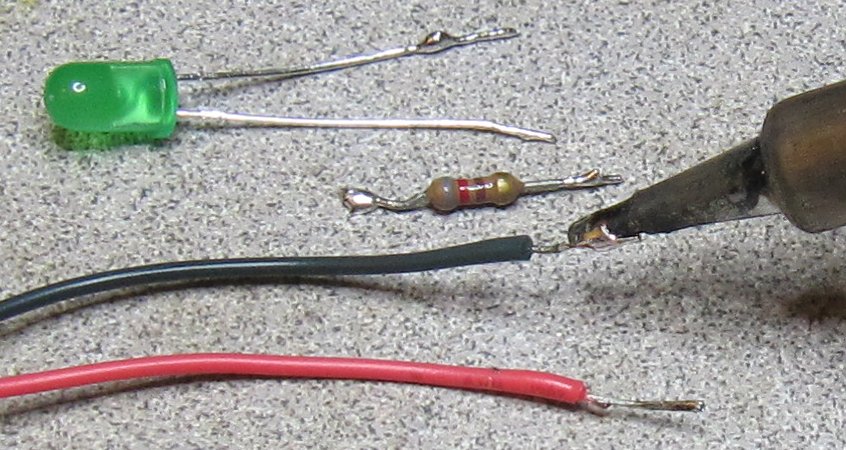

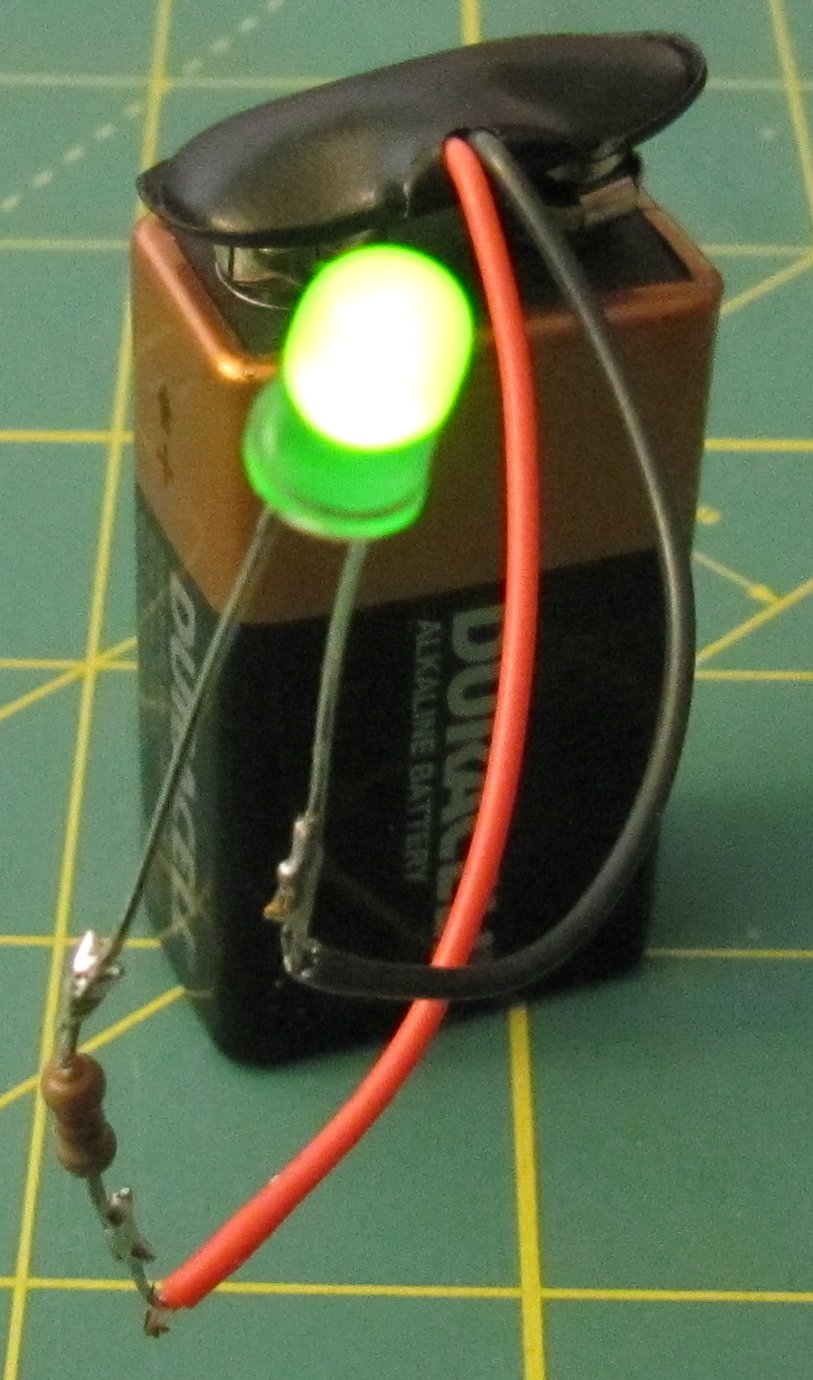

Here is a picture of the

parts:

The resistor is an 820 ohm. For a 5% resistor close to 900 ohm, we have

a choice between 820 and 910 ohms. The reason is that the resistor

manufacturers used to arrange the selected values so that any possible

resistance value would fit into at least one salable value. In this

way, there were no wasted resistors, even though the process control

was a bit lacking.

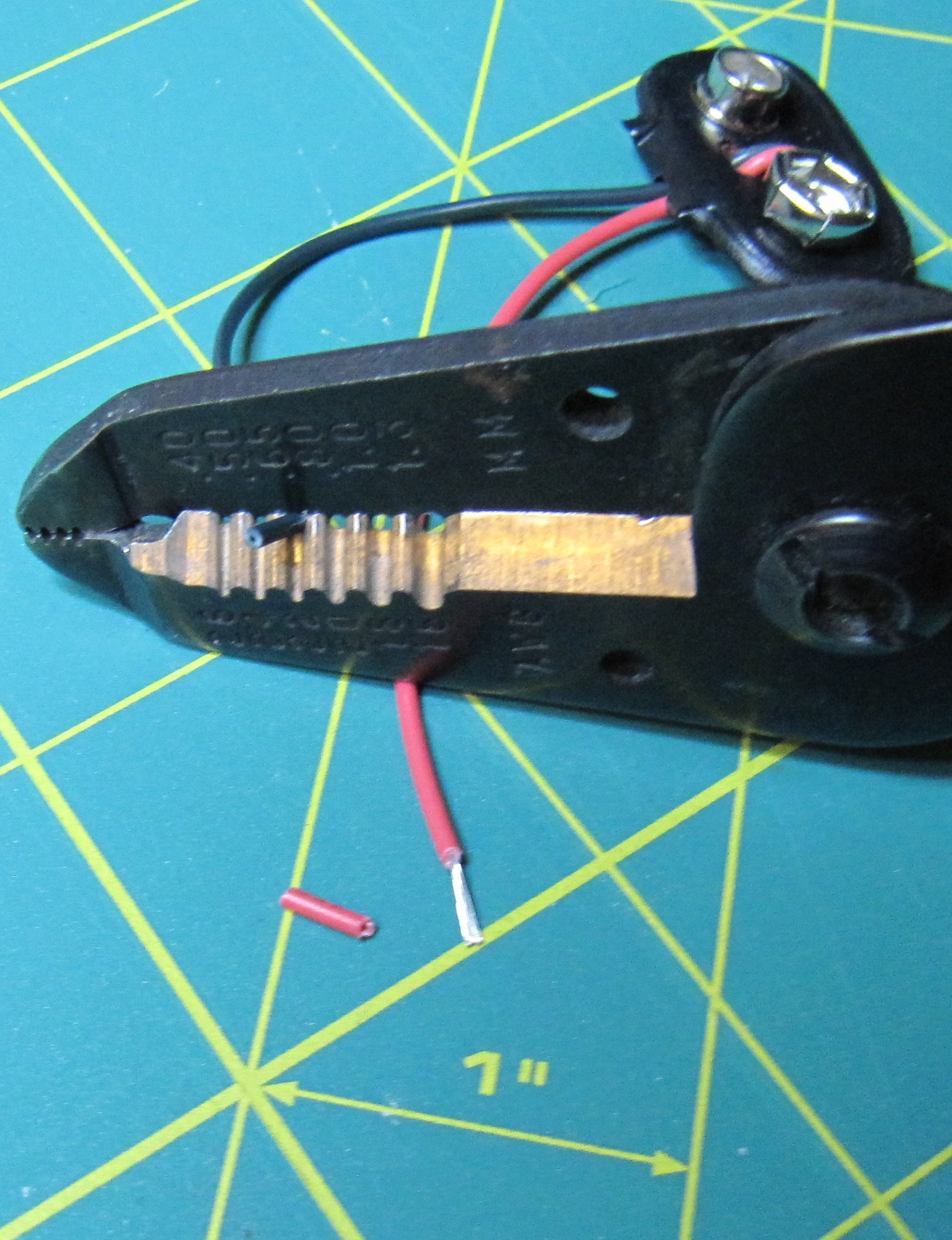

First thing to do is

to strip the wires on the 9v connector:

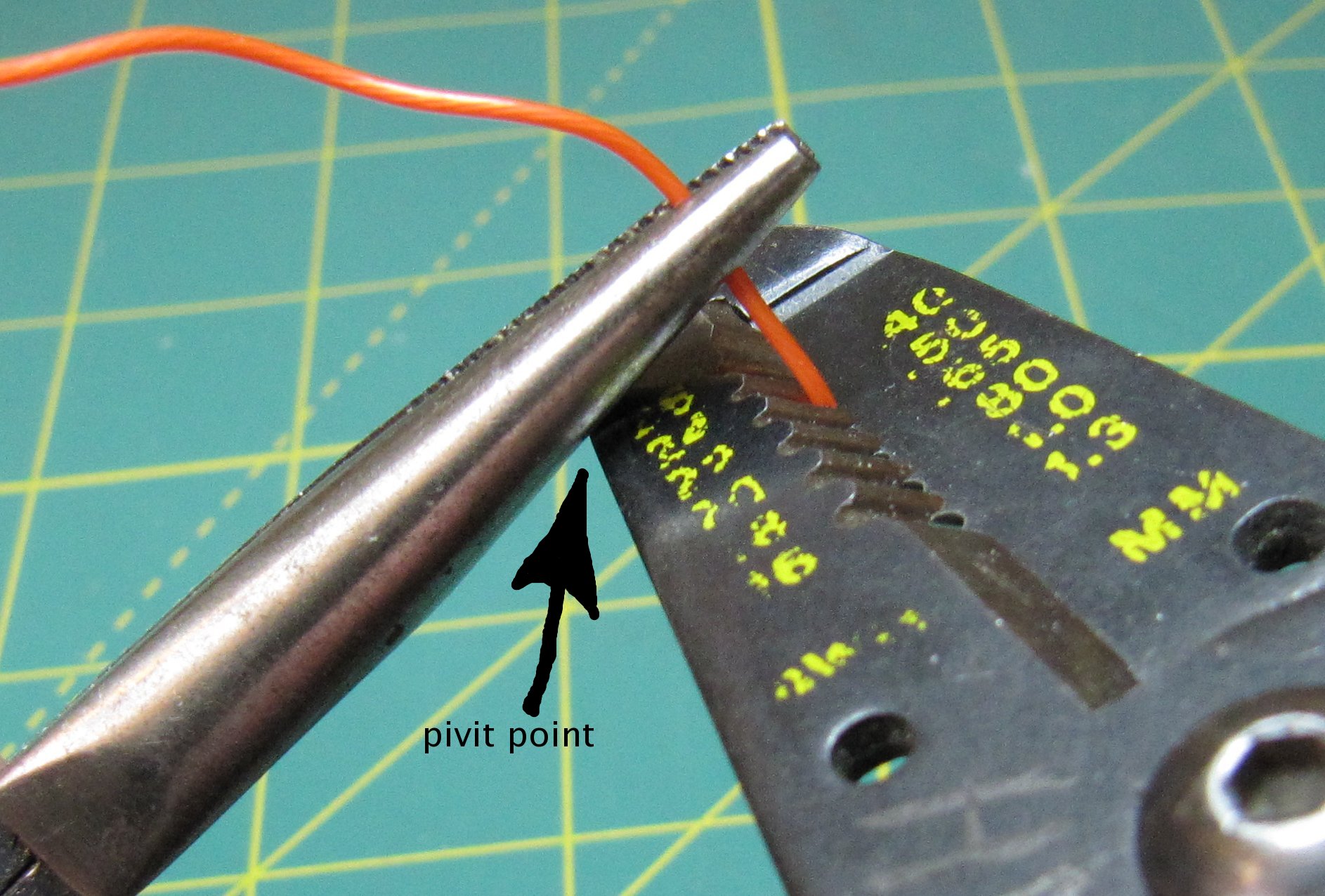

Using the wire stripper requires the selection of the correct position

for the wire size, then you place the wire into the stripper, clamp it

shut and pull the wire. The pulling part can be problematic because

sometimes the stripper will grab the wire and pull it out of the

insulation. This usually happens when the wire length is short. This

problem can be avoided by holding the wire with needle-nose pliers. The

pliers will compress the insulation enough that both the insulation and

the wire will be pulled out of the stripper at the same time. If you

grab the wire close to the stripper with the needle-nose pliers, you

will be able to lever the pliers against the stripper. The wire will

now come out of the stripper smoothly with no lengthening of the

stripped part verses the insulation.

After you have stripped a wire, it is a good idea to look at the end

with a magnifying glass and see if you have cut off some of the

individual strands of the wire. If there are a few strands left in the

removed insulation, the wire should be trimmed and stripped again while

using one of the larger sized positions in the wire stripper. If there

are missing strands, chances are good that the other strands are

damaged and will soon break. Damage to a strand would be any cut mark

(visible using a microscope). When the wire is bent back and forth

during normal use, any cut will get larger until the wire breaks.

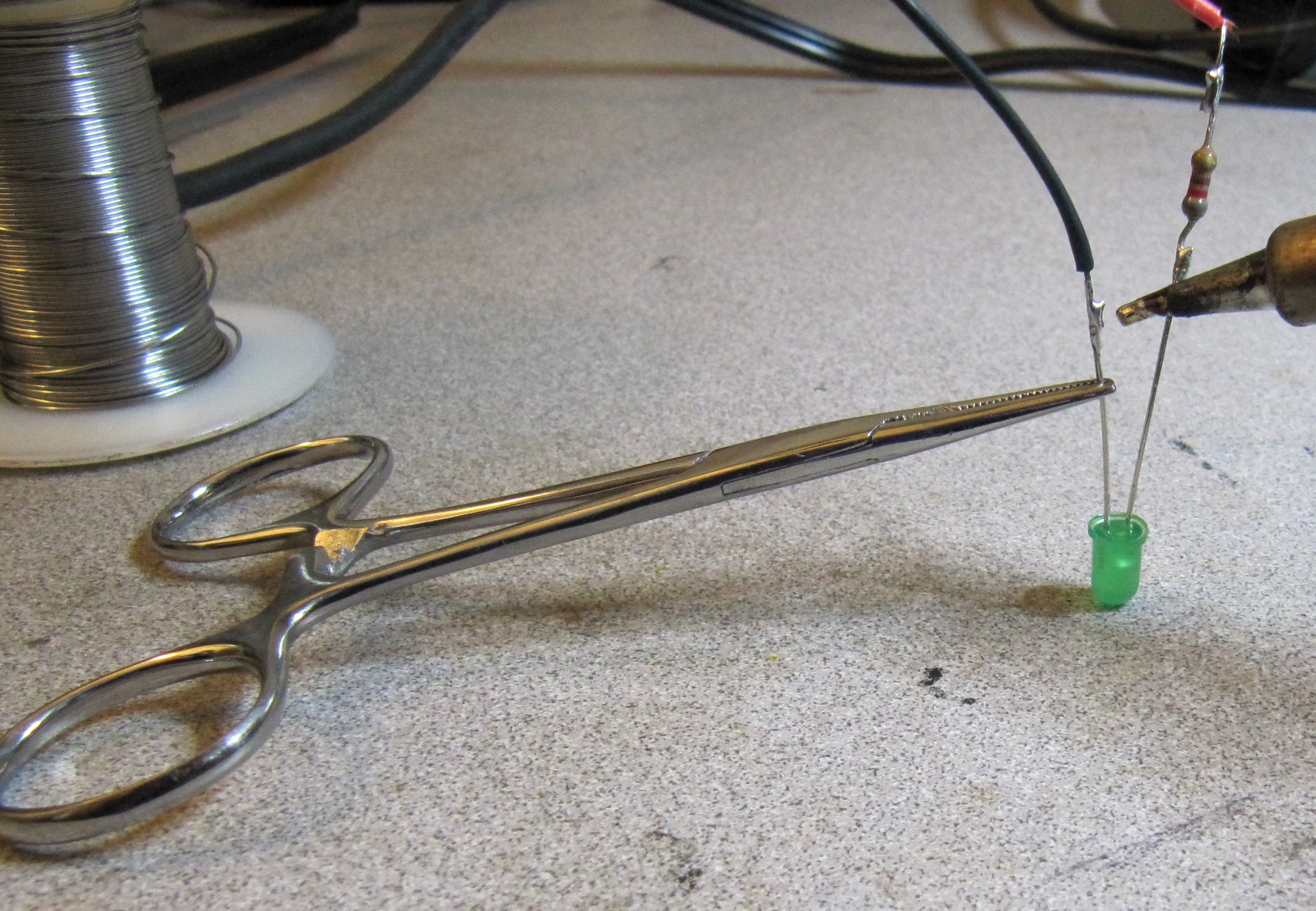

Next, we will put some solder onto all of the leads. This is called

“tinning” the leads.

The solder should be shiny and it should look like it has flowed evenly

onto the leads (concave fillets). If the solder looks like a small glob

that just dropped onto the lead, you can try melting the solder at the

same time as the tip of the soldering iron is touching the lead. The

smoke that rises from the solder is the flux burning. The flux cleans

the surface of the wire so that the the solder will attach to the wire

and flow over it, thus making a good connection. Once the flux has

burned away, more flux may need to be applied in order for the solder

to flow onto the surface of the wire. A clean tip is also necessary.

Wet the sponge and rub the tip of the iron on it for just a short

second. You should hear a hiss as the tip turns a bit of the water on

the sponge into steam. Add some solder to the tip and then rub the tip

on the sponge again. The tip should be really shiny after this.

Soldering is pretty important, so it is a good idea to do a web search

for soldering (wikipedia is a good place to start). There are

many courses and web pages that have been written on soldering.

Now we are ready to solder the parts together. Be sure that the longer

lead of the LED is connected to the resistor, and that the resistor is

connected to the red wire. The side of the LED that is flat should be

connected to the black lead.

The LED is now ready to test. Be sure to keep the leads from touching

each other. Electrical tape or heat shrink tubing may be put on the

leads to keep them from touching, but this is a demonstration, so I

left the leads so that all of the connections may be seen. If the

exposed conductor of the red wire were to touch the exposed conductor

of the black wire, the battery would become drained and possibly

overheat. A shorted battery can leak toxic chemicals and a few high

power batteries can actually explode, depending on the type of battery.

A car battery could cause the wires themselves to turn red hot and this

would seriously burn your hands if you were holding the wire at the

time.

If you are interested in how LEDs are made and why they light up, there

are many pages on the web. One good place is: LightEmittingDiodes.org

There are many theories about why LEDs work, but these theories were

not used to make the first LED. The first LED was discovered by H. J.

Round in 1907 while he was touching wires onto a piece of carborundum.

People used to just get a crystal and place the tip of a wire onto

different parts of it in order to form the diode for their crystal

radios. This was called a cat whisker. I think that this was the

phenomenon that was being investigated when the first LED was

discovered. H.J. Round applied 10v to the wire that he placed onto the

silicon carbide crystal and noticed that there was a glow. He wrote a

paper on it in 1907 and then that was it. He never made a dime on his

discovery.

In 1927, a Russian physicist,

Oleg Losev

rediscovered the LED and wrote many papers in different languages about

the light emitted by silicon carbide when a voltage was applied. It is

not known if he made any money for his re-discovery either.

The LED was made practical by General Electric in 1962 through the work

of Nick Holonyak. Nick was working for GE at this time, so at

least he got paid something while he was working on it.